Van bi Nordsteam NST-2PK

Liên hệ báo giá

- Model: NST-2PK

- Xuất xứ: Thổ Nhĩ Kỳ

[TABS_R id=12416]

Mô tả đặc điểm van bi model NST – 2PK hãng Nordsteam

To have clean fluid like all other valves is vitally important for ball valves. Therefore, filter should be certainly put before the valve. Otherwise, filty fluid will cause deformation on the surfaces of ball and gasket in a short time. In order to have a long life-cycle for these valves, valves should be turned on and turned off at least once in fifteen days. By taking their structures into consideration, they should be used just for the positions of fully turn -on and turn-off, not for decreasing or increasing. Sudden turn-on and turn -off should be avoided to eliminate the risk of water-hammer. They are suitable to use in the media of low pressure steam, gas, cold/hot/superheated water installations and the fluids that have no properties of acid and alkalli.

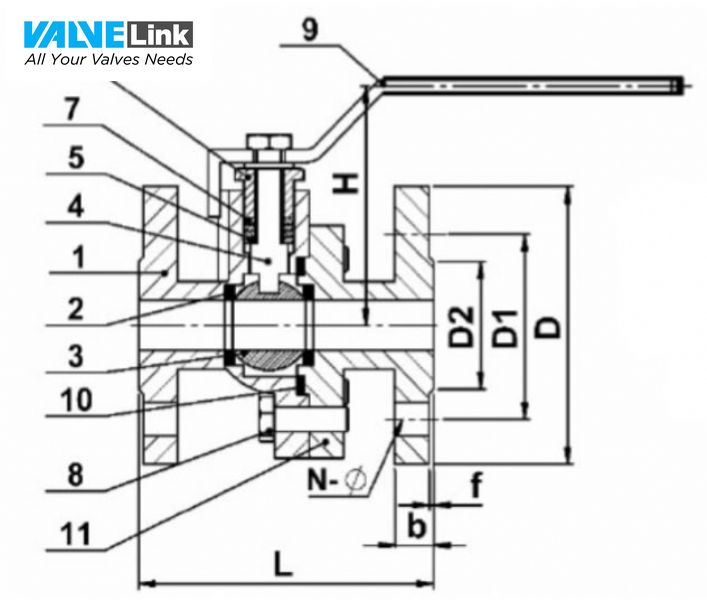

[TABS_R id=12416]Cấu tạo van bi NST-2PK

Thông số kỹ thuật:

1-Design and manufacture:DIN EN 13789:2002

2-Face to face dimension:DIN EN 558-1:1995

3-End flange dimension:DIN EN 1092-1:2002

4-Inspection and test:DIN EN 12266:2003

| SPARE PARTS | ||

| No | Description | Material |

| 1 | BODY | GG25 & GGG40.3 |

| 2 | SEAT | PTFE |

| 3 | BALL | STAINLESS STEEL / 304 & 316 |

| 4 | GASKET | PTFE |

| 5 | PACKING GLAND | PTFE |

| 6 | TIGHTENING WASHER | 35 |

| 7 | BOLT | 35 |

| 8 | HANDLE | A3 |

| 9 | GASKET | PTFE |

| 10 | SHAFT | STAINLESS STEEL / 2Cr13 |

| 11 | BONNET | GG25 & GGG40.3 |

| DIMENSIONS | |||||||||

| Size | PN 16 | ||||||||

| L | D | D1 | D2 | b | H | N-Ø | f | ||

| DN15 | 115 | 95 | 65 | 45 | 14 | 86 | 4*14 | 2 | |

| DN20 | 120 | 105 | 75 | 58 | 16 | 95 | 4*14 | 2 | |

| DN25 | 125 | 115 | 85 | 68 | 16 | 100 | 4*14 | 2 | |

| DN32 | 130 | 140 | 100 | 78 | 18 | 105 | 4*18 | 2 | |

| DN40 | 140 | 150 | 110 | 88 | 18 | 121 | 4*18 | 3 | |

| DN50 | 150 | 165 | 125 | 102 | 20 | 136 | 4*18 | 3 | |

| DN65 | 170 | 185 | 145 | 122 | 20 | 161 | 4*18 | 3 | |

| DN80 | 180 | 200 | 160 | 138 | 22 | 180 | 8*18 | 3 | |

| DN100 | 190 | 220 | 180 | 158 | 24 | 222 | 8*18 | 3 | |

| DN125 | 325 | 250 | 210 | 188 | 26 | 260 | 8*18 | 3 | |

| DN150 | 350 | 285 | 240 | 212 | 26 | 280 | 8*23 | 3 | |

| DN200 | 400 | 340 | 295 | 268 | 30 | 340 | 12*23 | 3 | |

| DN250 | 450 | 405 | 355 | 320 | 32 | 380 | 12*27 | 3 | |

| OPERATING CONDITIONS | |

| MAX. ALLOWABLE PRESSURE PMA (BAR) | 24 |

| MAX. ALLOWABLE TEMPERATURE TMA (ºC) | -15 ~ 200 ℃ |

| MAX. OPERATING PRESSURE PMO (BAR) | 16 |